- Fiber Optic Cables

- Fiber Optic Cable Accessories

- Copper Cables

- Copper Cable Accessories

- High Density Data Center Wiring System

- Intelligent Management Wiring System

- Security Cables

- Conference AV Cables

- Cabinet and Accessories

- Optical modules

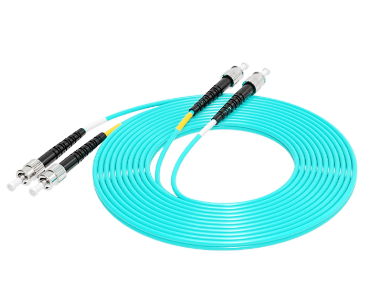

- Fiber optic patch cords

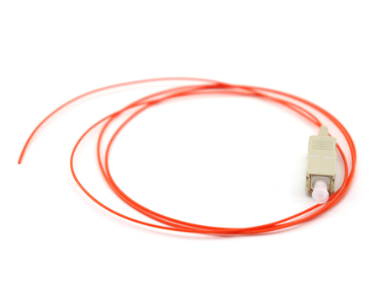

- Fiber optic Pigtails

- Fiber optic patch panels

- Fiber optic adapters

- Fiber Transceiver

- Fiber optic terminal boxes

- Wall-Type Fiber Optic Panels

- Pre-terminated fiber optic cables

- Fiber optic distribution boxes(ODF)

- Fiber optic distribution cabinets (ODF)

- Outdoor waterproof connection boxes

- Optical Transceiver Management Rack

- Telephone optical transceiver

- Industrial grade switch

-

FC Multi-Mode Fiber Optic Pigtail 50/125 OM3

-

SC Multi-mode 10 Gigabit Pigtail ,50/125, OM4

-

FC Single Mode Pigtail, OS2, 1M

-

LC Multimode 10 Gigabit Pigtail ,50/125, OM4-300M,1M

-

SC Multimode 10 Gigabit Pigtail ,50/125, OM3-300M,1M

-

LC Multimode 10 Gigabit Pigtail ,50/125, OM3-300M,1M

-

SC Multimode Pigtail , OM2 , 50/125 ,1m

-

LC Multimode Pigtail , OM2 , 50/125 ,1m

-

ST Single Mode Pigtail, OS2 ,1M

Fiber optic pigtails

Unlike fiber jumper(fiber optic patch cords) cables boasting pre-installed connectors at both terminations, pigtail patch cords exclusively feature one connector, while the opposite end presents unterminated fiber.

Multi-Strand Pigtails

The marvel of multi-strand pigtails resides in their construction, comprising multiple tightly buffered fibers enveloped within a cable jacket. This design allows seamless cutting, splicing, and termination, ushering in a realm of possibilities for organizations. The rapid customization and deployment of pigtail fiber cables cater to network terminal applications. The conventional quest for the perfect connector for each end of a jumper cable is rendered obsolete. With pigtails, the approach is simplified – a quick cut and splice, and the network is ready for action.

Utilizing Fiber Optic Pigtails Cable

The industrial and manufacturing landscape teems with varied requirements, not all necessitating pre-terminated connectors on both ends of a fiber patch cord. Often, the need arises for factory-installed connectors at just one end. In these scenarios, harnessing fusion or mechanical splices across digital connections proves advantageous. This is particularly true when integrating these connections into larger panels, networks, or expansive fiber optic deployments. Pigtail solutions shine in tight spaces and innerducts, where maneuverability is essential.

Multimode Pigtail

Cutting Fiber Optic Patch Cords

While the prospect of purchasing and severing a fiber optic patch cord into two pigtail fiber optic cables is conceivable, it unveils two potential quandaries – cost and complexity. Dual-connector cables tend to be pricier than their pigtail counterparts. Moreover, imprecise cuts on existing patch cords could spell pigtail fiber failures. Opting for purpose-built pigtail patch cords ensures the optimal performance and throughput requisite for high-value fiber optic applications.

Perks of Fiber Optic Pigtails

The multi-strand fiber optic pigtail cable revolutionizes the routing of substantial strand volumes through protective pathways or innerduct lengths. One end features effortless connections, while the other is ripe with multiple splice options. This equates to heightened flexibility in applications demanding voluminous data transfer, such as telecom signaling and industrial device controls. Additionally, the deployment of multiple strands within a solitary jacket reduces the cabling footprint.

Distinguishing Female and Male Connectors

Within the realm of fiber optic pigtails, two connector variants take center stage – female and male connectors. Female connectors find their home in patch panels, often paired. Alternatively, a single-fiber female connector can be affixed to an endpoint or another fiber run through patch fibers. Male connectors, on the other hand, directly plug into optical transceivers.

Kolorapus Fiber Optic Pigtails

Embarking on the quest for your ideal fiber optic pigtail finds a fitting companion in Kolorapus. Our repertoire includes both multimode and single mode fiber optic pigtail solutions, meticulously tailored to meet diverse network requirements. The gamut of multi-strand multimode pigtails showcases LC, SC, ST, FC, and MPO connectors, catering to 62.5/125 and 10gig applications. On the single mode front, SC, LC, ST, FC, MU, and MPO options stand tall, complete with UPC or APC ferrules. Kolorapus takes the helm in delivering top-tier fiber pigtail options. Armed with over two decades of industry experience, our commitment to durability, reliability, and competitive pricing remains unparalleled. Customization stands at the forefront, with every cable crafted to precise client specifications.

Choosing the Optimal Connector for Your Needs

Selecting the most fitting connector hinges upon the nature of the fiber installation and the equipment in play. Although adapters present a workaround, a proactive approach entails pre-determining both the fiber and connector requirements. Notably, LC, SC, and ST connectors dominate the US landscape for networking and audio/video applications, with LC and SC taking the lead.

Multimode and Single Mode Pigtails

Uncertainty regarding the optimal fit for your application finds resolution in considering data volumes and distances. Multimode pigtails excel in high-volume transfers due to larger-diameter glass strands. However, over extended distances, the refractive limitations of multimode fiber optic signals manifest. Single mode pigtails employ narrower core fiberglass strands, delivering superior-quality, smaller-volume data output across considerable distances.

Multimode Pigtail Single Mode Pigtails

Tight-Buffered vs. Loose-Tube Fiber Optic Cables

Two main fiber optic cable types – tight-buffered and loose-tube – vie for attention, each tailored to distinct environments.

Tight-Buffered Cables

Engineered for indoor applications, tight-buffered cables emerge as robust contenders. Excelling in moderate-length LAN/WAN connections, extended indoor runs, direct burial, and even underwater settings, these cables boast a dual-layer coating: plastic and waterproof acrylate. This design shuns the gel layer but instead relies on acrylate to maintain core dryness, even during cable bends or compressions. The ease of installation reigns supreme, with no gel mess or need for elaborate fan-out kits for splicing and termination.

Loose-Tube Cables

The outdoor domain belongs to loose-tube cables, forged to withstand rugged environments. As the elder sibling in cable types, loose-tube cables come furnished with a semi-rigid protective sleeve, encapsulating the fiber core, cladding, and coating. These cables, when home to multiple optical fibers, ensconce each core within an individual sleeve, loosely bundled within an outer jacket. Water-resistant gel proves instrumental in shielding fibers from moisture, making these cables ideal for humidity-laden locales where gel-filled tubes can flex and contract with temperature fluctuations.

The difference between Fiber optic Pigtails and Fiber optic patch cords

Fiber optic pigtails exhibit a single pre-terminated connector on one end, coupled with bare fibers on the other. In contrast, patch cords display two or more pre-terminated connectors on each end, without any exposed fibers.

Fiber optic Pigtails Fiber optic patch cords

Fiber pigtails prefer unjacketed cables, often embracing the 90μm diameter variety. On the other hand, patch cords lean towards jacketed fiber cables, including the likes of 2.0mm or 3.0mm fiber.

Considering their distinct applications, fiber pigtails primarily thrive in fast fusion splicing, while patch cords thrive as connectors between optical transceivers, patch panels, and backbone networks.

And finally, a crafty technique—slicing a fiber patch cord into two—yields two pigtails. This maneuver is necessitated by the challenges of field-testing pigtails before they're spliced into equipment due to their unterminated ends.

A Glimpse into the Varieties of Fiber Pigtails

They're demarcated based on various factors, including fiber connector types and fiber types.

Fiber Types: Multimode and Single-Mode Pigtails

In the realm of fiber types, the classification splits into two—multimode and single-mode fiber. Multimode pigtails find their genesis in the 62.5/125μm or 50/125μm bulk multimode fiber cables, while single-mode pigtails arise from 9/125μm OS1 or OS2 bulk single-mode fiber cables.

Connector Types: LC, SC, ST, FC, MU, E2000, and More

Determining the connector type unfolds a spectrum of options, featuring LC, SC, ST, FC, MU, E2000, MPO, and others. Each type carries its unique properties and applications.

LC Fiber Pigtail: Characterized by compact form factors and high-density connections, LC connectors offer a space-efficient alternative. The pigtails come pre-assembled with LC connectors.

LC Fiber Pigtail

SC Fiber Pigtail: Also known as Subscriber Connector or Square Connector, SC connectors boast longevity and cost-effectiveness. They find their niche in both P2P and PON applications.

SC Fiber Pigtail

FC Fiber Pigtail: Leveraging metallic bodies and screw-type structures, FC connectors deliver accuracy. They find their place in diverse applications.

ST Fiber Pigtail: Exhibiting a different locking mechanism compared to FC connectors, ST pigtails cater to various sectors like telecom, industry, medical, and sensors.

ST Fiber Pigtail

Polish Types: PC, UPC, and APC

Polish types offer further distinctions among fiber pigtails:

PC Fiber Pigtail: Featuring physical contact polishing, this variant prevails in the telecom sector and data systems.

UPC Fiber Pigtail: The "ultra physical contact" type minimizes air gaps and lowers ORL. It dominates both single-mode and multimode pigtails.

APC Fiber Pigtail: With an "Angled physical contact" design, APC pigtails reduce back reflection, making them suitable for systems like CATV and FTTx.

Application Environments: Regular Indoor, Armored, and Waterproof Pigtails

Application environments reveal a trio of options:

Regular Indoor Pigtail: Cost-effective and designed for tighter bend radius, these pigtails are ideal for indoor use.

Armored Pigtail: Encased in stainless steel for added protection, these pigtails ward off damage from various sources.

Waterproof Pigtail: Boasting rugged connectors and reinforced jackets, these pigtails brave harsh outdoor conditions.

Fiber Counts and Constructions

The fiber count presents flexibility, with options ranging from single to multiple counts. Moreover, the structure of fiber pigtails varies, encompassing multi-fiber bundles, robbin pigtail, 0.9mm, and 2.0/3.0mm pigtail.

Fiber Pigtail Splicing

In the arena of splicing, two approaches shine:

Mechanical Splicing

Mechanical Splicing entails precise fiber alignment, enabling light transmission. It's straightforward and minimizes waste compared to epoxy/polished connector methods. While the initial investment is lower, the cost per splice is higher.

Fusion Splicing

Fiber fusion splicing harnesses high temperatures to fuse optical fibers seamlessly. It boasts strength and minimal loss. The cost per splice is lower, but the initial investment is higher due to the need for specialized equipment.

The Perfect Fit for Every Need

In the ever-evolving domain of fiber optics, the Kolorapus emerges as the go-to solution provider. With a diverse range of fiber optic pigtails, we cater to every connectivity need. Regardless of your scenario, count on us for unwavering support. Your fiber optic journey deserves nothing less.